Slide

STANDARD FRP

Fiberglass Reinforced Plastic (FRP) Panel are extremely durable and easy to sanitize.

Home / Wall Panels / Service Wall Panels / Standard FRP

Home / Wall Panels / Service Wall Panels / Standard FRP

The most trusted name in FRP wall panels since 1932

When interior walls require ultimate durability and consistent quality, Marlite standard FRP delivers proven performance. As the most specified in fiberglass reinforced plastic (FRP), we know the importance of maintaining sanitary conditions in high-traffic areas, ensuring code compliance, and protecting walls, even in moisture-prone environments.

That’s why with every Marlite FRP panel, you are guaranteed:

- Consistent 0.090-inch thickness for superior durability and impact resistance

- USDA/CFIA-approved for food-safe environments

- Fast, straightforward installation to reduce labor costs

- Easy-to-clean surface that stands up to harsh cleaning protocols

- Available in Class A and Class C fire ratings to meet building codes

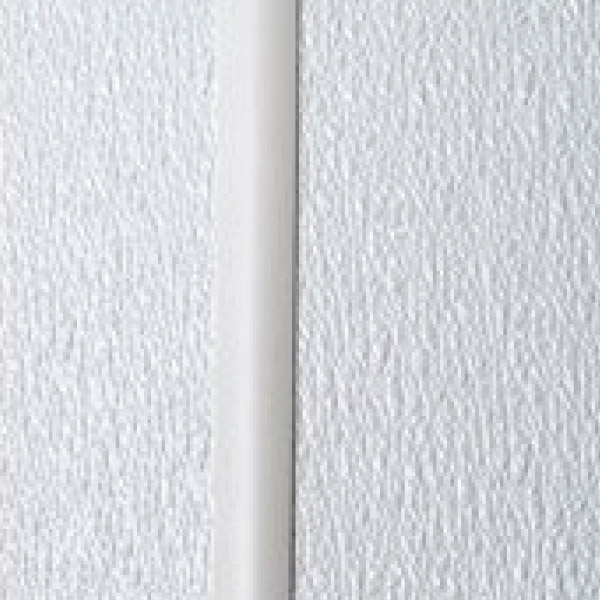

- Choice of smooth or pebbled texture in 4′ x 8′, 4′ x 9′, and 4′ x 10′ panels

Whether you’re specifying materials for a commercial kitchen, healthcare facility, or industrial space, Marlite FRP wall panels offer the ideal combination of durability, cleanability, and regulatory compliance that makes them the trusted choice of professionals since 1932. Get more information about our FRP material.

Features

Reliable, dependable Standard FRP panels

Marlite FRP is engineered for long-term resilience in demanding environments. With manufacturing excellence and premium features you can trust, our FRP panels ensure walls stay protected, clean, and code-compliant for years.

Superior Construction

Available in 4′ x 8′, 4′ x 9′, and 4′ x 10′ FRP boards and a choice of pebbled or smooth FRP, our wall panels are guaranteed 0.090-inch thickness for consistent quality.

Exceptional Durability

With high-impact resistance for busy commercial environments, our FRP paneling resists scratches, stains, and daily wear and stands up to harsh cleaning chemicals and protocols.

Moisture Protection

Marlite FRP protects walls from mold and mildew growth, making it ideal for wet and high-humidity areas. It’s USDA/CFIA approved for food service environments.

Safety Compliance

Third-party tested and certified, our FRP panels meet international building codes. Choose from a class A or class C fire rating.

Finish Options

Marlite FRP panel finishes and colors

Get Marlite FRP panels that fit your exact specifications. Our standard FRP comes in 4′ x 8′ and 4′ x 10′ sheets with your choice of textured or smooth FRP surface and a variety of standard colors. For specialized installations, 4′ x 9′ FRP panels are also available in select colors. Custom colors available; minimum order quantities may apply.

Pebbled FRP (*available in 4’ x 9’)

Smooth FRP

Check out great pricing on select overstock panels. Get them before they are gone!

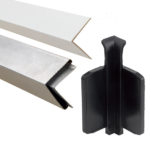

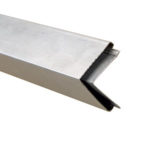

Trim Options

Installation

Quick and simple FRP panel installation

Transform your walls with professional results in less time. Marlite FRP panels install efficiently with basic tools and our proven step-by-step process:

Measure and cut FRP panels to size using a table saw.

Apply Marlite FRP adhesive evenly to panel back.

Position and adhere panel to prepared subwall.

For seam joints, install division molding under first panel edge.

Secure molding with staples along pre-sealed edge.

Place second panel against molding and repeat.

Pro Tips:

- Use only Marlite-approved adhesives for guaranteed performance.

- Allow panels to acclimate to room temperature before installation.

- Ensure subwall is clean, dry, and structurally sound.

- Keep proper spacing for expansion and contraction.

Download the Complete Installation Guide Here.

Inspirations

Standard FRP applications and project gallery

From busy commercial kitchens to high-traffic corridors, Marlite FRP wall panels deliver proven protection in thousands of installations nationwide. Explore how architects, facility managers, builders, and others are using our Standard FRP to create durable, easy-to-maintain spaces in restaurants, healthcare facilities, schools, manufacturing plants, and more.

By using our website, you agree to our Privacy Policy and Terms of Use, which explains our use of cookies and similar technologies.

© Copyright 2025, Marlite, Inc